Well pump systems are crucial for our daily water needs. But when breakers trip, it can be frustrating. A recent online chat explored this issue with 17 participants.

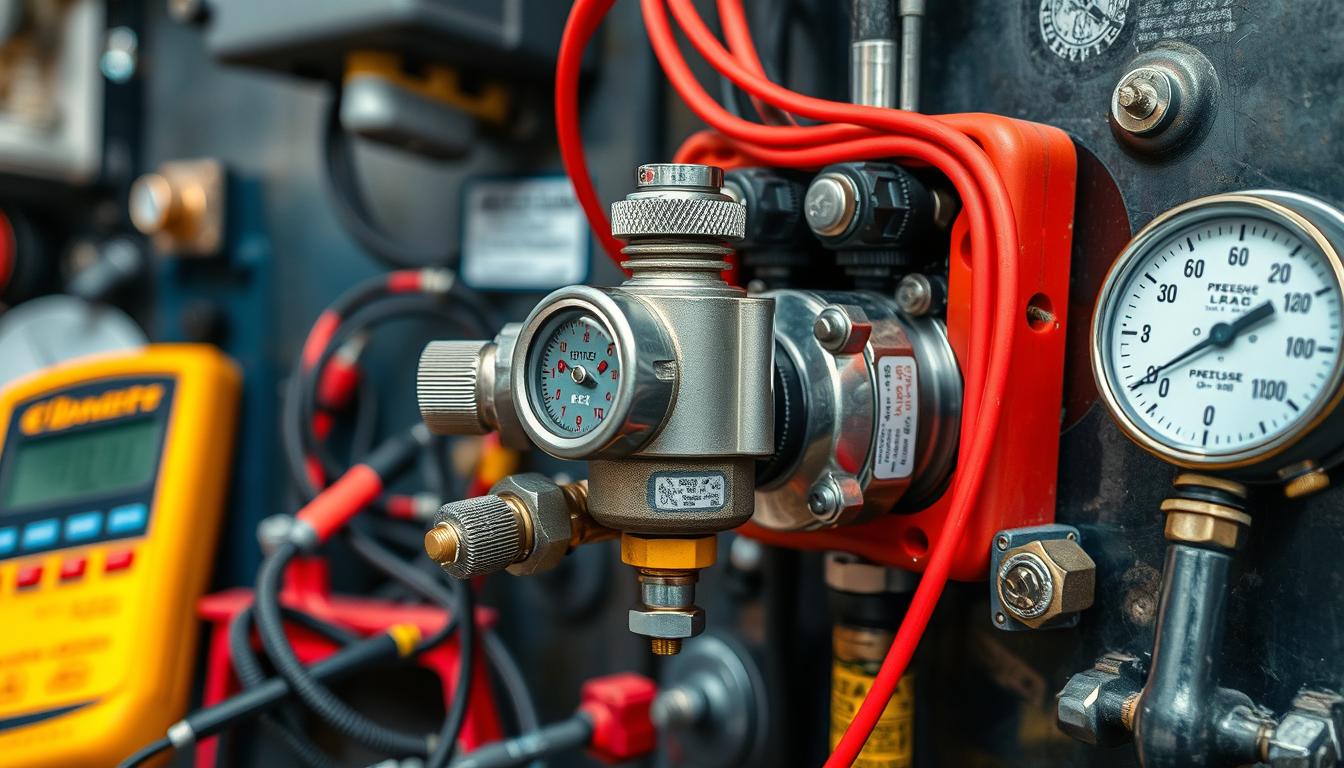

The discussion covered pressure switches, electrical problems, and compressor safety devices. Participants shared experiences using tools like the Fluke 323 Clamp Electrical Reader. They measured amperage readings between 32-36 amps with the pump.

Safety was a key concern. Participants warned against trial-and-error when replacing components, especially breakers. They stressed the importance of proper troubleshooting techniques.

Valuable tips emerged from the conversation. Checking the tank’s bladder was suggested to prevent short cycling. Upgrading to a 3-wire pump was recommended for fewer issues.

Regular maintenance was highlighted as crucial. Inspections can catch potential problems early. This helps prevent breaker trips in well pump systems.

Let’s explore pressure switches and their role in well pump systems. We’ll look at common issues and why bad switches can trip breakers. You’ll learn how to troubleshoot and maintain your system for reliable water supply.

Understanding Pressure Switches and Their Role in Well Pump Systems

Pressure switches are key parts of well pump systems. They keep pumps working safely and maintain steady water pressure. Let’s explore how these switches work and common issues they face.

What is a Pressure Switch?

A pressure switch monitors water pressure in well pump systems. It turns the pump on when pressure drops and off when it’s high enough. Mechanical switches are more common because they’re simpler and cheaper.

How Pressure Switches Work in Well Pump Systems

The pressure switch connects to the tank and pump. It activates the pump when tank pressure is low. When pressure reaches the cut-off point, it turns the pump off.

Pressure switches usually have two settings. Common ranges are 40-60 psi, 30-50 psi, or 20-40 psi.

- 40-60 psi

- 30-50 psi

- 20-40 psi

Mechanical pressure switches are most common in well pump systems. They use a diaphragm that presses against a piston and spring. The diaphragm moves as pressure changes, activating the switch.

| Diaphragm Material | Operating Temperature Range |

|---|---|

| Nitrile or Buna-N | -30°C to 100°C |

| EPDM | Up to 250°C (482°F) |

| Viton | Up to 200°C |

| PTFE | Up to 500°C (corrosive or high-abrasion environments) |

Common Issues with Pressure Switches

Pressure switches can develop problems over time. These issues affect how well the pump system works. Common problems include damaged contacts, wrong settings, and wear and tear.

- Damaged or corroded contacts

- Improper calibration

- Switch failure due to age or wear

These problems can cause various symptoms. You might notice high or low water pressure, or the pump turning on and off too often.

- High water pressure above the cut-off point

- Low water pressure

- Repeated on-off pumping cycles

- The pump not turning on

- A waterlogged pressure tank

- No water flow in the home

When testing a pressure switch on a well, ensure that power to the system is turned off to avoid accidents.

Understanding pressure switches helps maintain well pump systems. Recognizing signs of a failing switch allows for quick fixes. This ensures a reliable water supply for your home.

Reasons Why a Bad Pressure Switch Can Trip the Breaker

A faulty pressure switch can cause electrical issues in your HVAC system. These problems may trip the circuit breaker, cutting power to your AC unit. Understanding how a bad switch affects your system helps you fix and prevent future issues.

Electrical Issues Caused by a Faulty Pressure Switch

A bad pressure switch can lead to short circuits and ground faults. Short circuits happen when hot and neutral wires touch, causing a current surge. Ground faults occur when a hot wire contacts the ground wire, creating high currents.

These electrical problems can overload the circuit and trip the breaker. Loose or corroded wires in the switch can also contribute to these issues. Regular HVAC maintenance is key to spotting and fixing these problems early.

Overloading the Circuit Due to Pressure Switch Malfunction

A faulty pressure switch may fail to turn off the well pump at the right time. This causes the pump to run longer, drawing more power than the circuit can handle. The excessive current can overheat the system and trip the breaker as a safety measure.

Regular inspections and timely replacements of pressure switches are crucial. This maintenance helps protect your HVAC system from damage and ensures it runs smoothly. Addressing switch problems quickly safeguards your AC unit and keeps it working reliably.