Our summer pool plans hit a snag when the pump lost pressure quickly. The water flow slowed, and the cleaner stopped moving. We learned this common issue can damage pumps if ignored.

Pool pump pressure loss often has simple solutions. Air leaks, cavitation, or blocked skimmers can cause problems. Addressing these issues quickly is vital for a healthy pool.

Let’s explore why pool pumps lose pressure. We’ll guide you through troubleshooting and fixing the problem. Understanding these issues helps keep your pool clean all summer.

Common Causes of Pool Pump Pressure Loss

Is your pool pump losing pressure? This can be frustrating. Let’s explore some common causes and solutions for this issue.

Proper water flow is essential for a clean pool. By addressing these problems, you can keep your pool pump running smoothly.

Blocked Baskets and Skimmer Box

Clogged baskets often cause low flow in pool pumps. Check the skimmer basket by the pool and the pump basket inside.

Debris can restrict water flow in these baskets. Empty them regularly to maintain optimal water circulation.

This helps the system prime fully and operate at maximum capacity.

Low Water Level in Pool

Hot weather and heavy use can lower pool water levels. This can reduce or stop water flow through the system.

For proper pool pump suction, keep water at least halfway up the skimmer box opening.

Monitor and maintain the right water level for best pump performance.

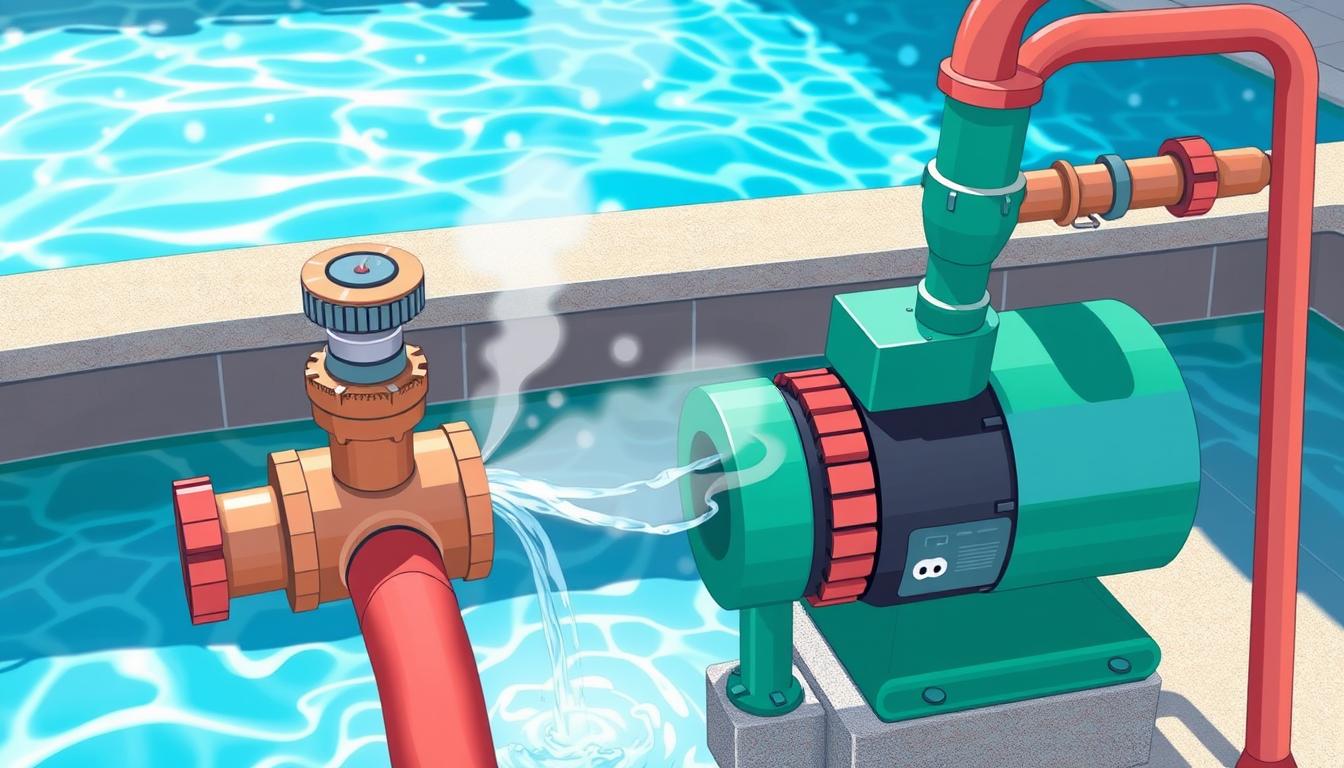

Air Leaks in Pump or Pipes

Leaky fittings and worn O-rings let air enter the pump. This causes a big drop in water pressure.

Check valves, pipe fittings, and the pool pump’s pressure relief valve for leaks. Fix them quickly to prevent pool pump low water flow.

A well-sealed system keeps your pool pump working efficiently.

Regular maintenance, such as emptying baskets, monitoring water levels, and checking for leaks, is key to avoiding pool pump pressure loss and ensuring a clean, enjoyable swimming experience.

Understanding these issues helps you maintain your pool pump. Take action to keep your pool clean and inviting all season long.

Checking and Priming Your Pool Pump

A pool pump losing pressure quickly needs inspection and proper priming. Priming fills the pump with water, creating suction to draw water from the pool. This keeps water circulating and prevents pump damage.

Proper priming is vital for optimal water circulation. It helps maintain a clean and inviting pool throughout the swimming season.

Inspecting the Pump Basket and Lid

Check the clear pump lid for water. If it’s empty, follow these steps:

- Turn off the pump’s power supply.

- Carefully unscrew the pump lid, making sure not to misplace the O-ring.

- Remove and clean the pump basket thoroughly.

Priming the Pump with Water

After cleaning the pump basket, it’s time to prime the pump. Here’s how:

- Detach any connected suction cleaners and remove the vacuum plate.

- Clean out the skimmer basket to ensure unobstructed water flow.

- Fill a bucket with water and pour it into the pump until the water level reaches about halfway up the inlet pipe.

- Lubricate the O-ring and securely replace the pump lid.

- Turn the pump back on and observe the water flow.

Troubleshooting Priming Issues

If priming problems persist, try these troubleshooting tips:

| Issue | Solution |

|---|---|

| Pump won’t prime | Rotate the multiport valve handle to “recirculate” with the pump off, then attempt priming again. |

| Air leaks | Inspect the pump and pipes for any visible leaks or loose connections, and repair as needed. |

| Low water level | Ensure the pool water level is high enough to cover the skimmer opening, allowing water to flow into the pump. |

| Persistent Issues | If priming issues persist, turn off the pump, shock the pool with chlorine, and seek professional assistance. |

Remember, proper pool pump priming is crucial for maintaining healthy water circulation and preventing damage to your pump. By regularly inspecting and priming your pump, you can ensure your pool remains clean and inviting throughout the swimming season.

Filter Problems That Cause Low Pressure

Your pool pump might lose pressure due to a filter issue. A dirty filter can reduce water flow. The pump struggles to push water through dirt buildup. Sand, cartridge, and DE filters need regular upkeep to prevent low water flow.

Dirty or Clogged Filter Media

Sand filters use sand to strain out impurities. They are usually 2 to 4 feet wide. Cartridge filters have fine, pleated mesh cylinders that trap debris.

DE filters have the most surface area, often 24 to 72 square feet. They use diatomaceous earth powder to filter contaminants. Over time, any filter media can clog, causing pressure loss.

Backwashing and Cleaning Filters

To fix water flow and pressure, clean the filter media. For sand and DE filters, start with backwashing. If that doesn’t work, try the “recirculate” setting.

If normal flow returns, backwash again. Persistent problems may mean replacing the sand or DE. Cartridge filters need different care.

Remove the cartridge with the pump off and valves closed. Hose it down or replace if needed. Lubricate O-rings and reassemble. Clean filters ensure good water circulation and prevent pressure loss.